Aerospace

Aerospace

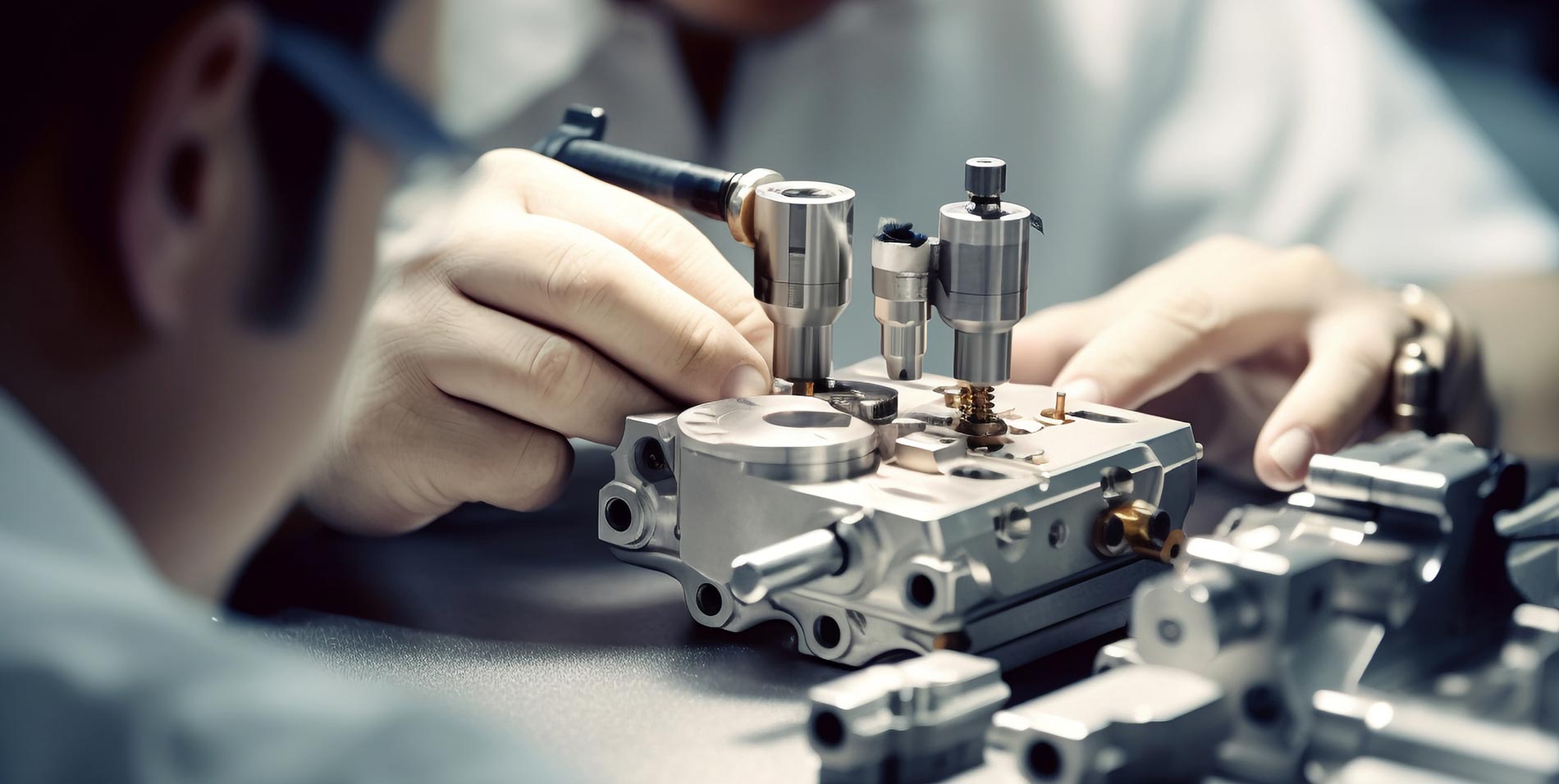

For the increasingly stringent product requirements such as weight reduction, high efficiency and large thrust proposed by the aerospace field, Shaanxi Zhituo...

2020 官网升级中!现在您访问官网的浏览器Equipment分辨率宽度低于1280px请使用高分辨率宽度访问。

Solid-state Additive Manufacturing (solid-state Additive Manufacturing) is relative to the use of liquid phase forming means (i.e., liquid phase welding) laser additive manufacturing, electron beam additive manufacturing, arc additive manufacturing, etc., and the proposed new concept of additive manufacturing, its forming means is Solid phase welding. At present, the developed solid phase additive manufacturing methods are: diffusion welding additive manufacturing, cold spray additive manufacturing, friction welding additive manufacturing, etc., among which the application of diffusion welding additive manufacturing is the most mature. Shaanxi Zhituo team focuses on diffusion welding additive technology for more than 20 years.

The design idea of layered physical manufacturing is used

LOM: Laminated Object Manufacturing

At present, the company has provided key technologies and products for aviation, aerospace, ocean engineering, rail transit, hydrogen energy, nuclear energy, solar thermal power, thermal power, petrochemical, electronic information, injection mold, instrumentation and many other fields.

For the increasingly stringent product requirements such as weight reduction, high efficiency and large thrust proposed by the aerospace field, Shaanxi Zhituo...

Provides a large number of R & D and test products for the aviation field, and a number of products have passed the test and assessment.

For the increasingly stringent product requirements such as weight reduction, high efficiency and large thrust proposed by the aerospace field, Shaanxi Zhituo...